Mixing & Blending

Our mixing and blending vessels are designed and manufactured to meet the highest standards of hygiene required in today’s industries. They cover a wide variety of cooking, mixing and blending applications across the whole range of products.

The systems can be developed, configured and tailored to your needs. Thanks to our extensive experience in the production of various soups, sauces and the other Food and Beverage Processing and Cosmetics Processing, S4 Engineering is familiar with the requirement and state-of-the-art technology in the hygienic processing industry.

Processes:

- Mixing

- Dispersing

- Emulsifying

- Vacuum Processing

- Heating (direct or indirect)

- Cooling (direct or indirect)

Applications:

- Baby foods

- Cheesecake

- Chocolate

- Coatings

- Cream

- Custard

- Desserts

- Flavourings

- Food oils

- Fruit Juices

- Fruit toppings

- Glucose

- Health drinks

- Ice cream

- Jelly

- Pastry

- Quiche

- Sauces

- Soya products

- Yogurt

- Mayonnaise (low and full fat)

- Ketchup

- Soups

- Ready meal component

- Salsa, tapenade

- Hummus

- Pates

- Fruit preparations

- Lotions and creams

Heat Treatment

For in-vessel heat treatment, a range of jackets is available, with either steam/hot water for heating products, or chilled/cold water for cooling. S4 has specially engineered its system to allow the same jacket to be used for clients dealing with both heating and cooling. Alternatively heat treatment can be achieved externally (e.g. via plate heat exchangers) or by a combination of internal and external heating and cooling.

Systems:

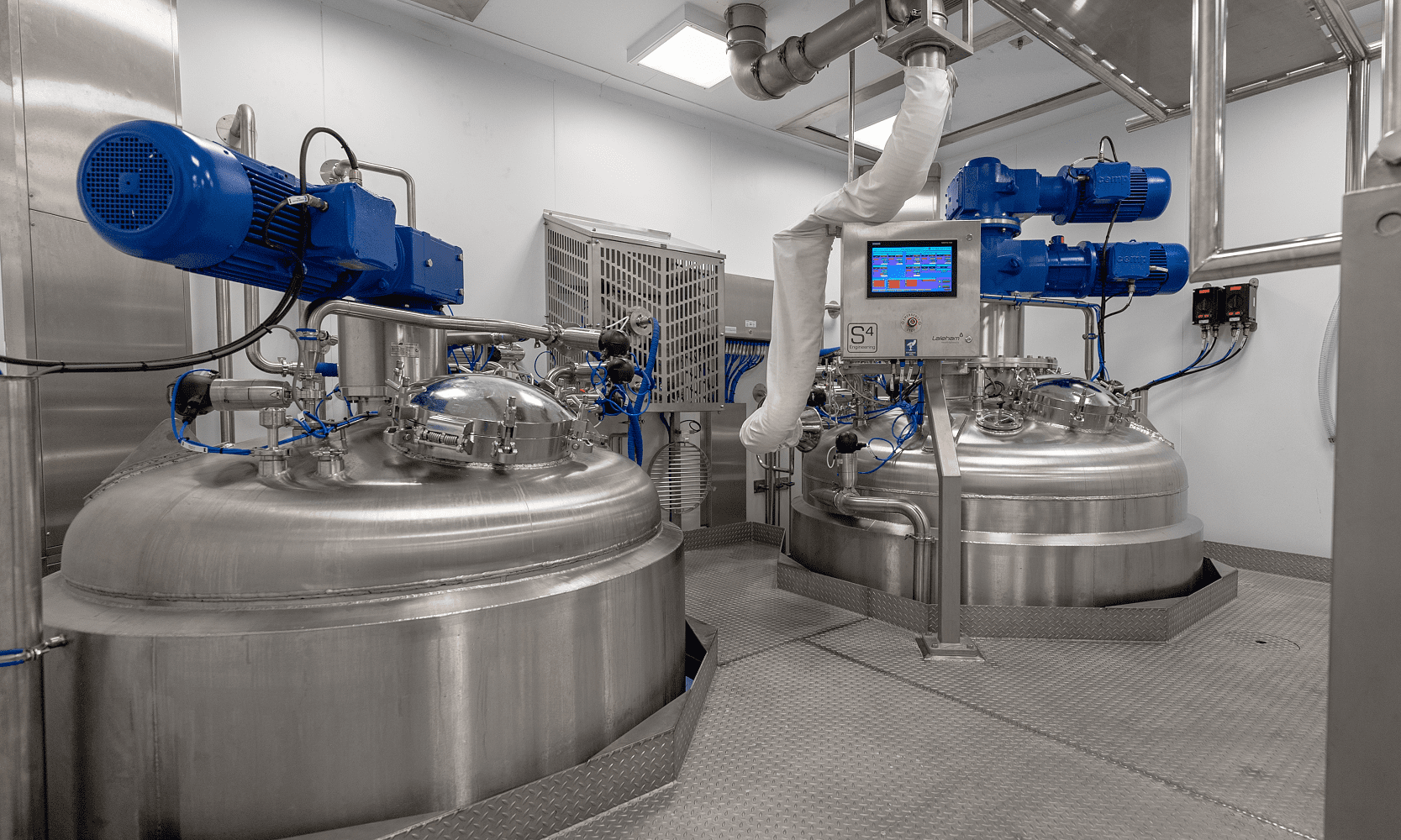

A mixing and blending system can be a simple as a vessel with agitation through to a fully skid mounted PLC controlled system with heating, cooling homogenisation and powder incorporation among the possible features that can be included. The majority of systems is designed, coded and built in-house by the S4 Engineering team at our Peterborough headquarters. This also allows a link into internal factory network for data acquisition.

Options:

- Steam injection

- Heat and cooling jacket

- Integrated measuring systems

- Cleaning (CIP)

- Load cell systems

Agitation is one of the keys to achieving the required product and a number of agitation types are available.

- Turbine

- Propeller

- Shear

- Gate

- Scraped surface

Case Studies

Pharmaceutical & Cosmetics Company

This £1m contract for a large pharmaceutical and cosmetics manufacturer included the installation of two reactor mixing vessels, one with a 6,000 litre capacity and the other with a 3,000 litre capacity.

You can view the full case study here.

Get In Touch

If you have any questions please fill in and submit the form below and one of our dedicated team will get back to you as soon as possible.