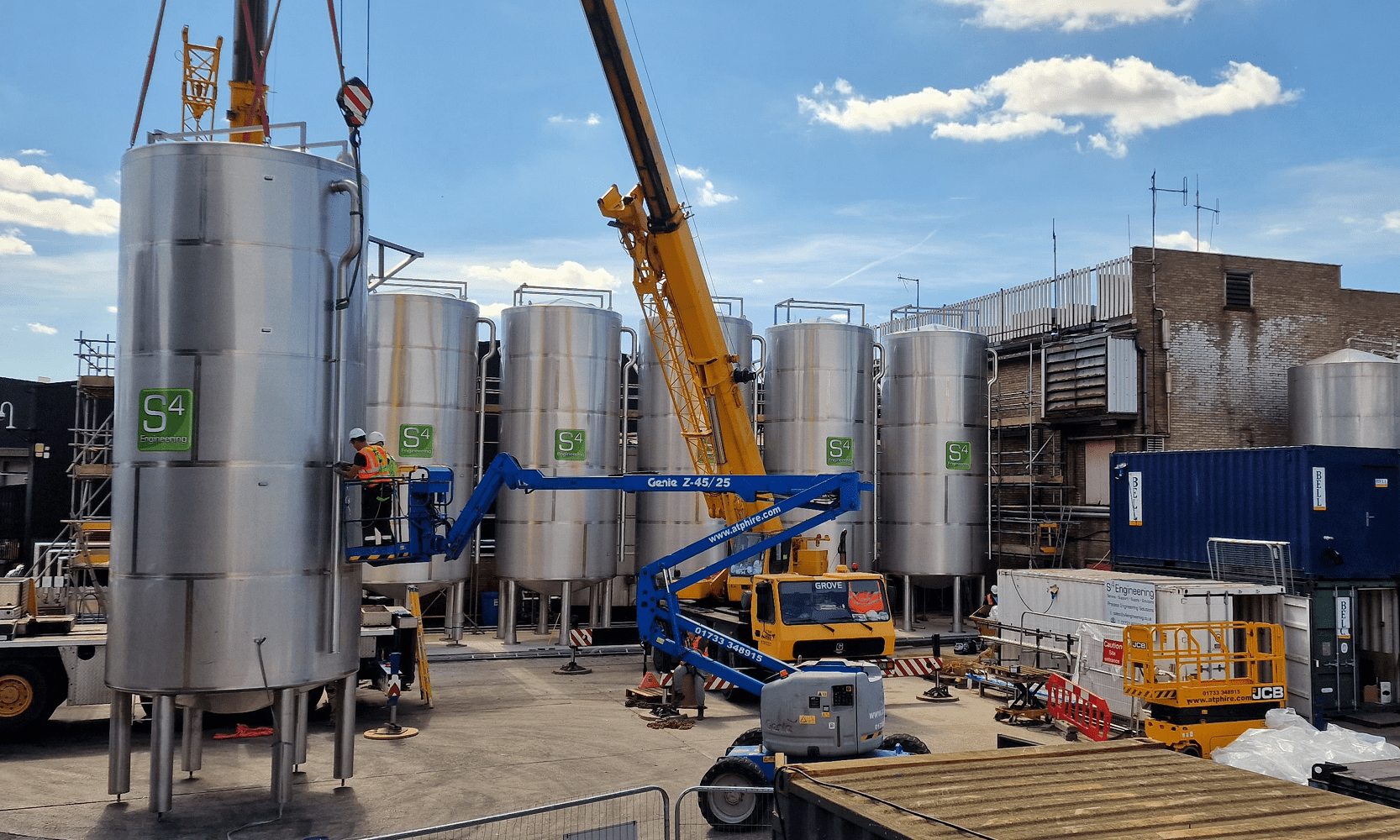

Storage, Holding & Transfer

S4 Engineering’s range of Storage, Holding, Transfer Vessels and systems have been carefully developed to maintain a quantity of liquid ingredients in a stable and hygienic state, ready for use in the further stages of your production process.

Vessels

A variety of features include agitation, heating/cooling systems sterile air top blanket systems, level measurement and more. In this way they become a flexible buffer to both large-batch and low-flow production processes.

Mobile Transfer & Holding vessels come in range of capacities to suit the clients requirements.

A complete range of vessel types is available:

- Single skin

- Jacketed for heating and/or cooling (e.g. dimple or plain)

- Insulated

- Clad (e.g. fully welded stainless steel, rivetted, plastic coated steel)

- Agitated (e.g. turbine, impellor, gate, high shear)

For pressure/vacuum applications, vessels can be built to the British Standard Code of Practice (PD5500), which ensures they comply with the latest European Pressure Equipment Directive (PED)

Mixproof Valve Block

S4 Engineering’s design capabilities allow us to develop the valve clusters and manifolds into complex matrices as required.

Our aim are to centralise the distribution of multiple ingredients in an enhanced and efficient control environment.

Particularly suited to the processing of dairy, juiced and brewed products, an S4 Valve Matrix can be applied to include various lines, typically allowing the cleaning of one tank or process area whilst another is in use.

Case Studies

Jams & Spread Producing Company

This £1.25m contract involved the installation of six 50-ton liquid sugar tanks, providing a major plant upgrade for this jam and spread manufacturer. A range of associated systems were also installed, including a recipe management and control systems integration package.

You can view the full case study here.

Greencore Spalding

Seeking to expand their production of sugar-free Deli mayo, Greencore in Spalding commissioned us to supply and install two 4m3 stainless steel vessels. Large enough to store an entire day’s worth of mayo, the vessels were also outfitted with clean in place equipment such as pumps for optimal hygiene.

You can view the full case study here.

Get In Touch

If you have any questions please fill in and submit the form below and one of our dedicated team will get back to you as soon as possible.